Learn about products

Don't know exactly how to choose? Here is knowledge to help you find the optimal Ringfeder solution for your needs.

Don't know exactly how to choose? Here is knowledge to help you find the optimal Ringfeder solution for your needs.

It’s the nature of your transportation that tells which is the optimal coupling equipment for your vehicles.

The heavier loads and harsher conditions, the more critical it is to choose sturdy quality equipment. Here, a seemingly oversized coupling may well pay off by its higher resistance to wear and damage, with a longer service life as a result.

For the long-haulier, with few stops and smooth roads, comfort could be prioritised. A shock-absorbing coupling on a liquid transportation truck and trailer will reduce jerks and vibrations, resulting in a smoother drive and less wear on the vehicles.

These are some typical transport applications. If you look at their nature and requirements accordingly, you will better know how to think when selecting a coupling solution for your vehicles.

For distribution, e.g. to stores and restaurants in city centres, smaller and lighter trucks are often used. Such vehicles are more agile and are easier to manoeuvre in city traffic and they are rarely combined with a trailer. However, if you need the option to occasionally couple a trailer, a simple and light coupling would be a perfect choice.

Recommended Ringfeder trailer couplings

Regional hauling/distribution is often carried out with truck and trailer on good, public roads, and the transportation often includes liquid and bulk transports. Here, you should prioritise operational reliability and, depending on the type of goods carried, comfort.

Recommended Ringfeder trailer couplings

RF40 A/B | RF40 AM/RL | RF45 A/B | RF50 A/B | RF50 AM/RL | RF50 A/B INT | RF50 AM/RL INT

Heavy transportation with a fully loaded truck and trailer put great demands on the coupling. To withstand the high forces a robust and sturdy 50mm coupling is the preferred choice. The air-assisted opening will add to the driver’s comfort and efficiency.

Recommended Ringfeder trailer couplings

Heavy load

Off-road driving with heavy payloads and repeatedly coupling and uncoupling means extreme stress and wear on the equipment. For such operation you will need a sturdy coupling with reliable operation that withstands heavy wear. The rugged ground can make opening strenuous and tricky. The air-assisted opening will add to the driver’s comfort and efficiency.

Recommended Ringfeder trailer couplings

Medium/heavy load

These applications often include off-road driving, short driving distances, heavy payloads, and repeatedly coupling and uncoupling. This will put much stress and wear on the equipment. You will need a sturdy coupling with reliable operation that withstands heavy wear. As the rugged ground in construction sites can make opening strenuous and tricky, air-assisted opening will be a great feature for saving time.

Recommended Ringfeder trailer couplings

Extreme load

For the really heavy loads a standard coupling will not be sufficient. Here, the attachment must be reinforced by additional bolts to the drawbeam in order to absorb the very large forces.

Recommended Ringfeder trailer coupling

On request

Medium/heavy load

Forestry and timber operation means repeatedly coupling and uncoupling, tricky turnarounds – sometimes off-road – and long distances on narrow and bumpy dirt roads. This puts much stress and wear on the equipment. You will need a sturdy coupling with reliable operation that withstands heavy wear. As the rugged ground in the forest can make opening strenuous and tricky, the air-assisted opening will add to the driver’s comfort and efficiency.

Recommended Ringfeder trailer coupling

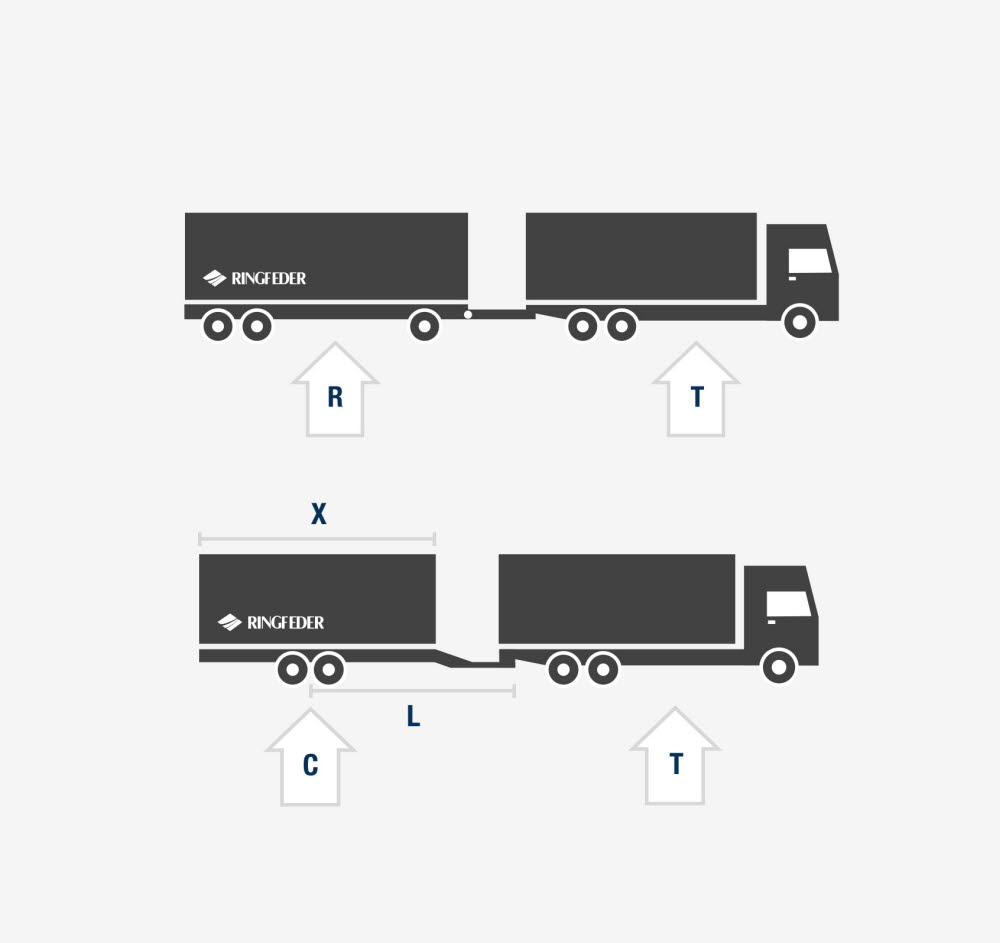

When towing a heavy trailer, the coupling equipment is affected by strong physical forces. The D-value is a calculated measure reflecting the forces a component is designed to withstand. A higher D-value means that the component can withstand higher forces and accordingly, it is a performance value for the component.

The D-value is used for hinged drawbars, where only horizontal forces need to be taken into account. For rigid drawbars also vertical forces apply. In such a case, the D-value is described as a Dc-value and the ability to withstand vertical forces is reflected in the V-value.

The unit for performance values is kiloNewton (kN).

Hinged drawbar – D (horizontal forces only)

Rigid drawbar – Dc + V (horizontal forces + vertical forces)

By your vehicle loads you can calculate the necessary performance of the equipment. Make sure to always be on the safe side!

Irrespective of type, make or model, the combined coupling equipment must withstand the physical forces when tugging a trailer. Simplified, these forces depend on the weight of the connected vehicles, and for road safety the equipment must be certified for a performance value equal or higher than the calculated value. You can calculate performance values for your vehicle combination with the Ringfeder Performance Value Calculator.

Reliability is most important to avoid unnecessary downtime. Accordingly, well-tried mechanical constructions will facilitate for the driver and reduce maintenance and repair. All Ringfeder products are most reliable with minimal service and maintenance required.

Repeatedly coupling and uncoupling can be time-consuming. Air assisted opening (AM/RL models) will reduce strain and save time for the driver.

Wear parts must eventually be replaced, and couplings may accidentally be damaged. Always make sure that coupling parts and service is available when ever and where ever you may need it. Ringfeder parts are available globally with minimal standstill as a result, should the accident occur.

The heavier transportation, the rougher and sturdier coupling will be needed. Accordingly, a 40 mm bolt will be good for light to medium transportation, while a 50 mm will be better for heavy transports. Note that the drawbar eye must match the bolt i.e., your choice of 40 mm or 50 mm will directly indicate which trailers are possible to couple.

When in doubt, remember that a stronger and sturdier coupling will always keep you on the safe side!

The models differ mainly by their performance and sturdiness i.e., how heavy loads and hard wear they withstand. Also, some models are available with air-assisted operation. The model variants in turn, are mostly different geometrical flanges and hole patterns for fitting the coupling to the drawbeam.

You can have most of the manual Ringfeder couplings in either the A or the B variant.

A = Short hand lever in upper position

B = Long hand lever in lower position

The original Ringfeder Air Module / Red Line (AM/RL) adds the convenient pneumatical opening of the coupling. Another advantage of the original is the 50 percent higher closing power compared to a standard coupling. This makes coupling and uncoupling faster and safer. The air-assisted operation will save time and improve productivity.

AM/RL couplings can be operated by your control unit of choice.

Compatible with

With a conversion kit, you can convert most Ringfeder A/B pin couplings into air-assisted Red Line couplings. This option adds to the flexibility of Ringfeder products and allows you to improve the performance of a product you have already invested in.

The international organization United Nations Economic Commission for Europe (UNECE) strives for the harmonization of vehicle regulations. The ECE certification confirms that a product is compliant with the standards stated by the organization. Two main regulations apply for Ringfeder products:

UNECE Regulation No. 55 (R55) – Regulations of mechanical coupling components of combinations of vehicles (i.e. trailer couplings, drawbars, draw beams, etc.)

UNECE Regulation No. 58 (R58) – Regulations for underrun protection devices

By the ECE certificate the product is guaranteed to meet quality and performance demands for safe operation and road safety.

Centre axle trailers use

These trailers have up to a maximum of three axles in the centre of the vehicle. A rigid drawbar on the vehicle frame forms the connection to the truck. The central position of the axle(s) enables the trailer to be steered. The drawbar installation is described as ‘rigid’ because it is fixed to the frame and cannot flex up or down independently to the vehicle. To improve driving characteristics, centre axle trailers are coupled as low down as possible below the truck.

Trailers use

The trailer is steered using a separate pivot joint. For this purpose, the rigid front axle of the trailer is housed in the chassis so that it can be turned via a rotating frame with a turntable, to which a drawbar (often called A-frame drawbar) is attached. Since this drawbar is hinged it must be supported when the trailer is parked. Also, there is some kind of height-adjustment device so the drawbar eye can be levelled to the guiding funnel when coupling to a truck.

A hinged drawbar will not put a vertical force on the coupling (other than the weight of the drawbar itself, which is negligible), while a rigid drawbar on a heavily loaded centre axle trailer will add substantial vertical forces to the coupling.

Accordingly, couplings that cannot withstand vertical forces can only be used with hinged drawbars.

The towing eye is as essential as any other component in the truck and trailer coupling chain. It is always a good idea to select a high-quality drawbar eye. A high-quality eye will better resist wear and accordingly, reduce visits to the workshop for replacing worn-out bushes. A high-quality product will provide a longer service life and reduced total cost of ownership. Ringfeder drawbar eyes comply with applicable regulations and standards.

Mounting options

There are different options for mounting the towing eye to the drawbar:

In the event of a rear-end collision, the underrun protection system prevents smaller vehicles from becoming lodged underneath the truck or trailer. Ringfeder underrun protection devices are complete systems adapted for perfectly fitting to the major truck brands, respectively, and the modular and flexible system enables customised solutions at short lead times. All components are fully tested and certified in compliance with international regulations.

Since the underrun protection is a critical safety solution, it is governed by strict legal requirements. This increases safety and security for both the driver and other road users.

Directive UNECE R58 governs regulations on underrun protection.

According to UNECE R58 all components must be certified together as a protective system. Thus, it is not permitted to mix components from different manufacturers, not even if the components are individually certified.

Since September 1, 2019, revision 2 (R58.02) is replaced by revision 3 (R58.03). In order to increase road safety, the latter regulation R58.03 puts radically higher demands on the underrun protective devices, according to strength and dimensions.

For a transition period, R58.03 applies to all new type-approved vehicles. From September 1, 2021, R58.03 applies to all newly registered vehicles.

National or regional exemptions may occur.